Auger Powder Filler Machine – Auger Filler

Product Specification :

Automatic Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling Dry Syrup Powder in bottles.

The incoming dry bottle sterilized is fed through the in feed Turn Table with suitably guided on the moving delrin flat conveyor belt at the required speed for feeding. There are two separate filling head mounted on machine top plate in the same line. When bottle reaches to the first filling station, it will be held by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets signals from sensor magnetic clutch starts to rotate which is mounted on auger shaft. It will fill the desired amount of powder to the bottle through auger, where rotation time is previously saved in PLC control. After filling of first bottle pneumatic piston goes back and release the first bottle to move on conveyor, By the same time second bottle also moves along with the first bottle in empty condition. In second filling head same operation will be performed but this time second bottle get filled and first bottle moves further for next operation. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle get filled with powder as per set value pneumatic system will not going to release the bottle.

Salient Features:

- Total Compact c GMP model.

- All parts and assemblies coming in contact with powder and rubber stopper are made of S.S.316 and easily removable for mandatory Autoclaving/ Sterilization.

- "NO BOTTLE, NO FILL" System eliminates wastage of costly powder.

- Conveyor driving is through High quality imported Gear motor

- Machine speed can be adjusted by A.C. Frequency drive, which is time saving.

- Machine is provided with delrin conveyor belt to avoid sticking of vial on conveyor.

- Single track bottle movement, reduces setting of supporting guide rails and semi skilled person can also easily operate the machine.

- Pneumatic bottle holding system is connected with auger rotation, which eliminates chances of bottle transfer before completion of filling operation.

- No change parts are required for any change in bottle diameter from 30 to 120 ml.

- Imported Gear Motor for Conveyor drive.

- A.C. Frequency drive for Conveyor drive.

- "No Bottle, No Filling" System.

- Pneumatic bottle holding system.

Technical Specification :

| Model | SBAF-60 | SBAF-D-100 |

| Direction | Left To Right. | Left To Right. |

| Production Rate | Up to 30 to 40 Bottles / Min | Up to 60 to 80 Bottles / Min. |

| Fill Capacity | 10 grms to 50 grms. (with different set of Auger and funnel) Fill range depending upon Bottle opening and bulk density of powder. | 10 grms to 50 grms. (with different set of Auger and funnel) Fill range depending upon Bottle opening and bulk density of powder. |

| Accuracy | ± 2% depending upon consistency and the Uniformity of bulk density of powder under controlled level of Humidity (i.e.35%) | ± 2% depending upon consistency and the Uniformity of bulk density of powder under controlled level of Humidity (i.e.35%) |

| No. of Heads | Single | Two |

| Electrical Supply | 1.00 HP For Main Drive. 0.25 HP for conveyor | 2.00 HP For Main Drive. 0.25 HP for conveyor |

| Power Requirement | 440 Volts, 3 Phase (4 wire System) 50 Hz. | 440 Volts, 3 Phase (4 wire System) 50 Hz. |

| Height of Conveyor | Adjustable from 850 To 900 MM | Adjustable from 850 To 900 MM |

| Dimensions | 1524 MM (L) X 1105 MM (W) X 1800 MM (H) | 2200 MM (L) X 1102 MM (W) X 1817 MM (H) |

| Net Weight | 400 KGS. (Approx.) | 550 KGS. (Approx.) |

| Gross Weight | 600 KGS. (Approx.) | 800 KGS. (Approx.) |

| Bottle Diameter | 25 MM To 70 MM MAX. | 25 MM To 70 MM MAX. |

| Height | 55 MM To 110 MM. | 55 MM To 110 MM. |

| Pneumatic Air | Filtered, oil free, sterile low pressure AIR at 5 kg/cm2 | Filtered, oil free, sterile low pressure AIR at 6 kg/cm2 |

We manufacture of Auger powder filling machine for bottle , container and jar for different product for foods, spices, cosmetic , chemical , nutraceutical , supplement , pharmaceutical , Agro products from 5 gm to 5 kg .

Auger filler machine with latest model Servo base systems with color operating touch screen , Stirring unit with gear box and motor , specials designed auger screw & funnel, container feeding systems pneumatic , star wheel, feed screw etc depending of shape and sizes, speed etc..

Stainless Steel slat conveyor with machine , gear box with motor for drive slat chain transporting of container with variable speed drive systems, bottle guide , emergency switch and attached with sealing machine / capping machine for further process.

Flowchart

Shree Bhagwati

Shree Bhagwati India

The following accuracy error values of powder spiral filling are reference values, and the actual accuracy error values still need to be based on the customer’s product test:

| The volume of each filling unit | Tolerance |

|---|---|

| 0.1 g – 1 g | 5% |

| 1 g – 10 g | 3% |

| 10 g – 100 g | 2% |

| 100g plus | 1% |

An Auger powder filler machine, also known as an auger filler, is a specialized machine used for accurately filling powdered or granular products into containers. It utilizes an auger mechanism to measure and dispense a predetermined amount of powder into containers, such as bottles, jars, or pouches. Auger fillers are commonly used in industries such as food, pharmaceuticals, chemicals, and cosmetics.

Here are some key features and components typically found in an auger powder filler machine:

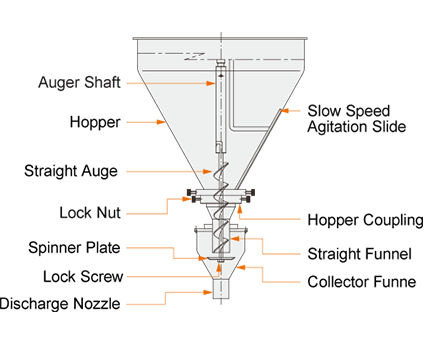

1. Auger Filling System: The auger filling system consists of an auger screw and a hopper. The auger screw is driven by a motor, which rotates the screw inside the hopper. The rotation of the auger screw creates a controlled flow of powder, which is then dispensed into the containers. The size and design of the auger screw can be customized to suit different types of powders and fill volumes.

2. Hopper: The hopper is a reservoir that holds the powdered or granular product. It feeds the product to the auger screw for dispensing. The hopper can have various capacities depending on the production requirements. Some hoppers may also include agitation mechanisms to prevent the powder from compacting or bridging, ensuring consistent flow.

3. Auger Filling Controls: The auger filler machine includes controls for setting the desired fill volume. This can be done through a control panel or an operator interface. The controls allow for precise adjustment of the auger rotation speed and duration, enabling accurate measurement and filling of the powder.

4. Container Handling Mechanism: Auger fillers may incorporate a container handling mechanism, such as a conveyor or indexing system, to transport the containers through the filling process. This ensures a consistent and efficient flow of containers, allowing the auger filler to fill them in a continuous manner.

5. Dust Collection System: Powder filling can generate dust, so some auger filler machines are equipped with a dust collection system. This system helps capture and control the airborne particles, maintaining a clean working environment and preventing cross-contamination.

6. Integration Options: Auger fillers can be integrated into existing production lines or used as standalone units. Integration options include synchronization with other equipment, such as capping machines or labeling machines, to create a complete packaging line.

7. Tooling and Changeover: Auger fillers often allow for tooling customization to accommodate different container sizes and fill volumes. Quick-change mechanisms are also common, allowing for easy and efficient changeover between different products or container sizes.

Auger powder filler machines provide precise and efficient filling of powdered or granular products. They help improve productivity, reduce product waste, and ensure accurate fill volumes, making them valuable equipment in various industries that deal with powdered or granular substances.