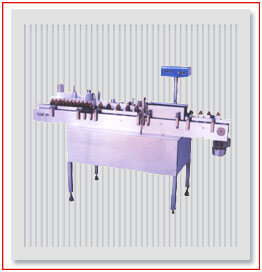

Bottle Sticker Labelling Machine – High Speed labeling machine

Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labeling Machine Mode OBSL-120 (S), Suitable for Labeling on Vials, Bottles and other round objects.

The Fully Automatic Labeling Machine incorporates latest sophisticated Micro Processor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system.

Salient Features:

- No change parts for container and label size

- Built In A.C. Freq. Drive System

- Output 40 to 150 labels per minute

- Fully stainless steel finish

- Optionally online coding system

- Suitable for Wrap-around and Overlap Labeling

Technical Details:

| Label Data Inputs | Not required due to In Built Automatic Label Length Detection System |

| Label Placing Adjustments | User Friendly And Simple |

| Pass-Word System | Fully Protected, Not required by operator |

| Voltage Fluctuations | Self-Protected for Voltage Fluctuations |

| Speed Variation | Single Point Speed Variation Control - Synchronizing all operations |

| Label Length | Unlimited Label Length |

| Maintenance | Virtually Maintenance Free Machine |

| Spool | Largest 400mm diamete |

Note: Dimensions & Technical Details are subject to change as per customers' requirement without any further notice

Machine Type: Bottle labeler Labeling Applications: Full bottle, partial wrap, orientation applications on cans, bottles, and other round container products Container Types: bottle round glass, plastic, metal and paper containersSelf adhesive labellers, also known as pressure sensitive labellers, are reliable and easy solutions for packaging lines.

Specification of the Equipment:

Machine’s Basics:

| Machine Name | Automatic Wrap Around Sticker Labeling Machine |

| Models Available | Servo Motor Based / Stepper Motor Based |

| Production Speed Per Hour | 2400 to 15000 Products per Hour (Speed Depends up on the Size of the Product and Operator Skills). |

| Number of Labeling Dispenser | Single Dispenser |

| Suitable for Products | PET / HDPE / GLASS / METAL TN / Aluminium |

| Application | Wrap Around Application on Round Bottles |

| Labels Requirement | Self Adhesive Sticker Labels in Roll Form having consistence 2 mm or 3 mm gaps between the 2 labels. |

| Label Material | Self Adhesive Cromo Paper Labels/ Filmic Labels / Transparent Labels |

| Label Roll Outer Diameter | Maximum 305 mm |

| Label Core ID | 75 mm |

| Maximum Label Length | 190 mm |

| Maximum Label Height | 225 mm |

| Label Dispensing Accuracy | +/- 1.5 mm |

| Rejection Ratio During Production | 1% |

| Bottle Separation Unit | Teflon or Rubber Molded Wheel Based Separation Unit |

| Working Height | 850 mm +/- 50 mm |

| Conveyor Length | 5 Feet |

| Machine Weight | Approx 250 Kgs |

A Wrap-around bottle labeling machine is a type of machine used in the packaging industry to apply labels onto round bottles. This machine is designed to efficiently and accurately apply labels to cylindrical containers, such as bottles, jars, and vials.

The process of labeling with a wrap-around bottle labeling machine typically involves the following steps:

1. Bottle Placement: The bottles are loaded onto the machine’s conveyor system or a feeding mechanism, which positions them in the correct orientation for labeling.

2. Label Roll: The machine uses a roll of labels that is fed into the labeling head. The roll contains pre-printed labels or blank labels that will be printed on-demand.

3. Label Application: As the bottles move along the conveyor, the labeling head applies the labels onto the bottles’ surfaces. The labeling head usually consists of a rotating drum or a belt that wraps the labels around the bottles.

4. Adhesive or Glue: The labeling machine may use different methods to apply adhesive or glue to the labels, depending on the specific design. It ensures that the labels adhere securely to the bottles.

5. Label Inspection: Some machines may include a label inspection system to verify the correct placement and quality of the labels. This step helps to ensure accurate labeling and can detect any errors or defects.

6. Bottle Discharge: Once the labels are applied and inspected, the bottles are discharged from the machine, ready for further processing or packaging.

Wrap-around bottle labeling machines are commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and household products. They provide an efficient and reliable solution for applying labels to round bottles, improving productivity and enhancing product presentation.

With 25 years experience in professional and excellent design team, provide unique labeling solutions depending on client requirement.