Self-Adhesive Labelling Machine - Labeler

Semi Automatic Vertical Type, User Friendly, Sticker (Self-Adhesive) Labelling Machine Mode OBMA-60, suitable for Labeling on Round Vials, Bottles and other round objects. The Machine incorporates latest sophisticated Microprocessor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system.

Salient Features:

- No change parts required for container & label size.

- Output between : 40 to 80 labels per minute.

- Fully stainless steel finish. Optionally online coding system.

- Suitable for Wrap-round and Overlap Labeling

Technical Specification :

| Label Data Inputs | Not required due to In Built Automatic Label Length Detection System |

| Label Placing Adjustments | User Friendly And Simple |

| Pass-Word System | Fully Protected, Not required by operator |

| Voltage Fluctuations | Self-Protected for Voltage Fluctations |

| Speed Variation | Single Point Speed Variation Control - Synchronizing all operations |

| Label Length | Unlimited Label Length |

| Maintenance | Virtually Maintenance Free Machine |

| Spool | Largest 400mm diameter |

We are reckoned manufacturer, exporter and supplier of Chemical Labeling machine that is used for Labeling Pharmaceutical Liquid, Pesticides Liquid, Agro Chemicals Pesticides, Automatic syrup Labeling machine, Liquid Medicine Labeling and Pesticides Bottle Labeling Line in India.

- Adhesive & Glue

- Agro Chemicals

- Car Care Products

- Chemicals & Solvents

- Confectionery

- Cosmetics

- Dairy

- Edible Oil

- Food & Beverages

- Home Care Products

- Juices & Syrups

- Liquid Disinfectant

- Liquor & Distilleries

- Lubricant Oil

- Paint & Colors

- Perfumes & Essential Oils

- Personal Care Products

- Pharmaceutical

- Spices & Masala

- Stationery

- Winery

A self-adhesive labeling machine, also known as a labeler or label applicator, is a device used to automatically apply labels onto various products, packages, or containers. It is widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics.

The labeling machine consists of several components that work together to ensure accurate and efficient label application. Here are the key components and their functions:

1. Conveyor System: The labeling machine usually includes a conveyor belt or system that moves the products through the labeling process at a consistent speed.

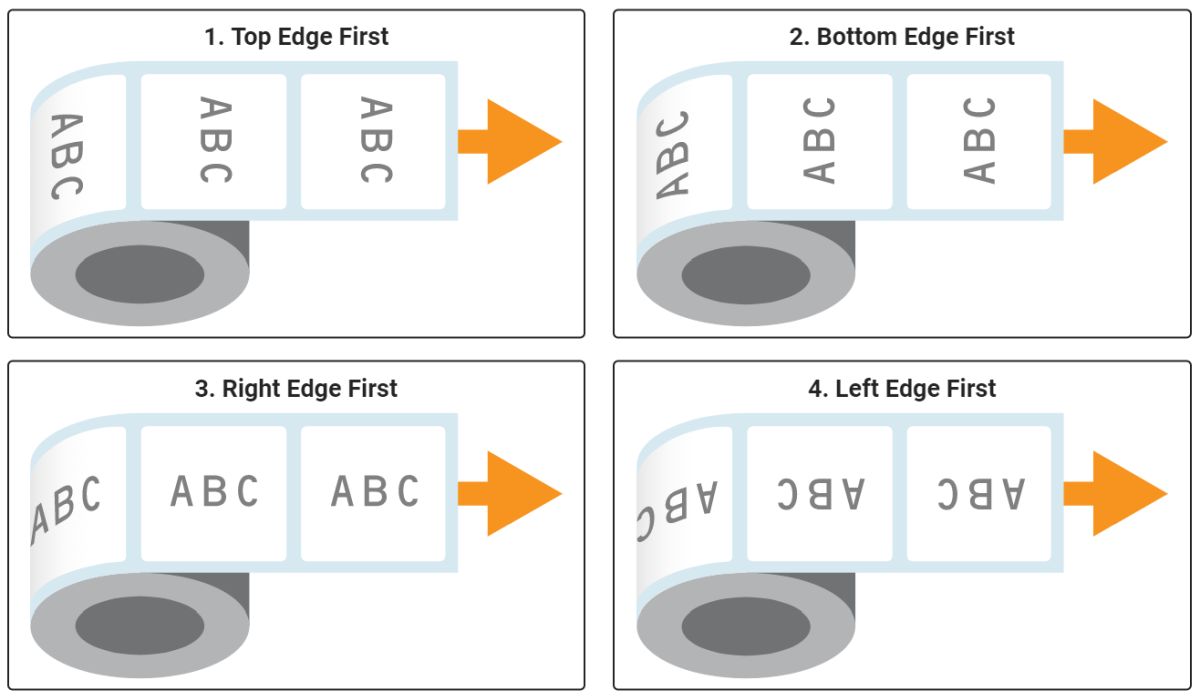

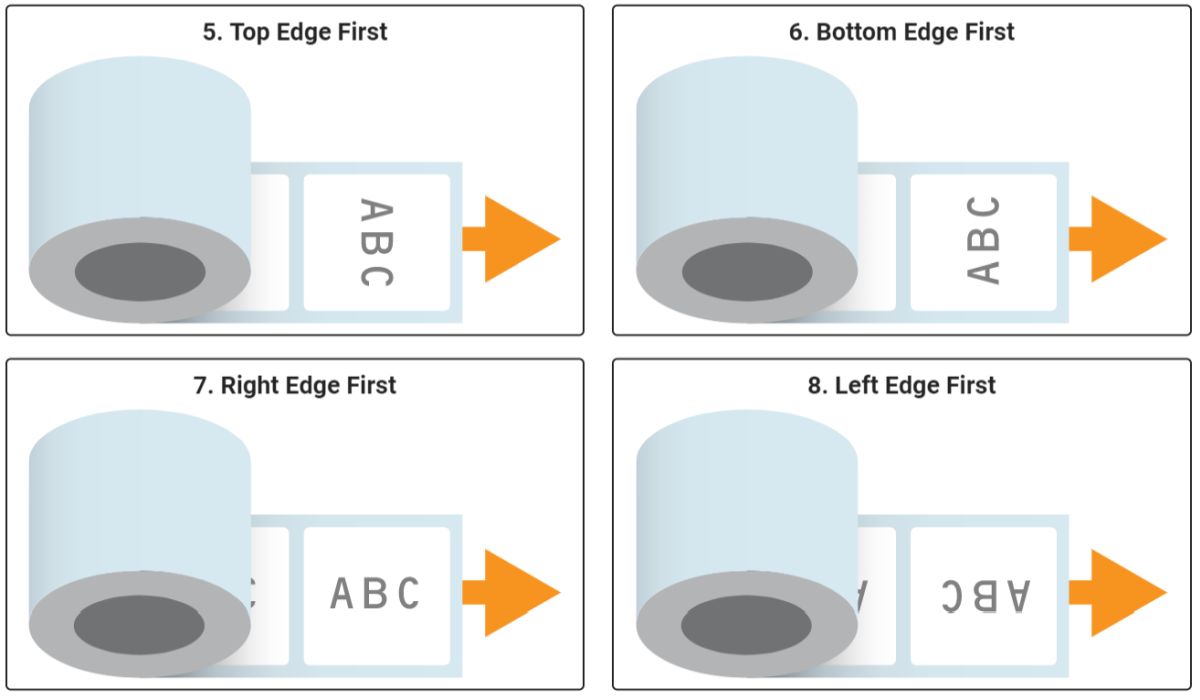

2. Label Roll Holder: This component holds the roll of labels that will be applied to the products. The label roll is usually placed on a spindle or a turret, allowing for easy unwinding of the labels.

3. Labeling Head: The labeling head is responsible for applying the labels onto the products. It consists of a mechanism that dispenses the labels from the roll and applies them accurately onto the products. The labeling head may use a variety of techniques, such as a vacuum drum, a tamp pad, a blow pad, or a wipe-on brush, depending on the specific application requirements.

4. Labeling Controls: The machine includes a control panel or interface that allows the operator to set parameters such as label size, application speed, and placement accuracy. Some advanced labeling machines may also have programmable features for different label formats or product types.

5. Sensors and Detection Systems: To ensure precise label placement, the machine incorporates sensors and detection systems that detect the position of the product and the labels. These sensors can be optical sensors, ultrasonic sensors, or other types of proximity sensors.

6. Integration with other Equipment: Labeling machines can be integrated into production lines or used as standalone units. In integrated systems, the labeler may communicate with other equipment, such as filling machines, capping machines, or packaging machines, to ensure synchronized operation.

The operation of a self-adhesive labeling machine typically involves the following steps:

1. Product Placement: The operator or an automated system places the products on the conveyor belt, ensuring proper spacing between them.

2. Label Roll Setup: The label roll with the desired labels is mounted onto the label roll holder.

3. Machine Setup: The operator sets the necessary parameters on the control panel, such as label size, placement position, and application speed.

4. Label Application: As the products move along the conveyor, the labeling head dispenses and applies the labels onto the products based on the predefined settings. The sensors and detection systems ensure accurate label placement.

5. Post-Labeling Operations: After the labels are applied, the products continue along the conveyor for further processing, such as packaging, sealing, or inspection.

Self-adhesive labeling machines offer advantages such as increased labeling speed, improved accuracy, and reduced labor costs compared to manual labeling. They can handle a wide range of label sizes and shapes, making them versatile for various products and packaging types.

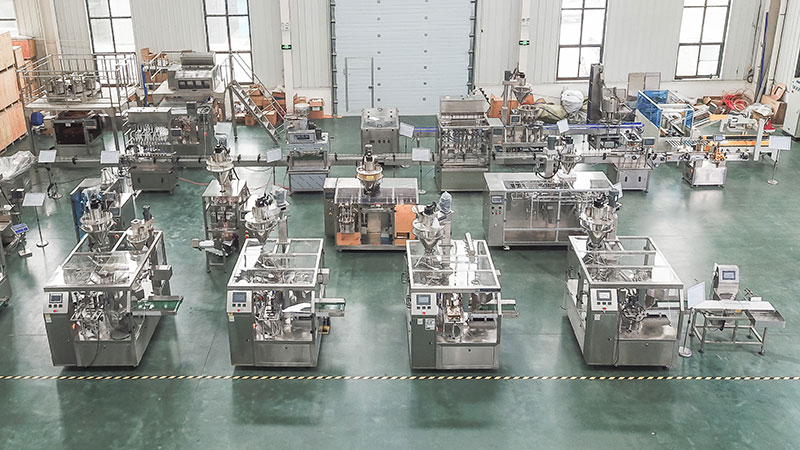

Automatic Sticker Labeling Machine Manufacturer and Supplier in India

OM Bhagwati Labelling is a reputable manufacturer of advanced Automatic Sticker Labeling Machines for Bottles, Jars, Vials, Ampoules, based in Ahmadabad, Gujarat, India. We specialize in providing top-of-the-line Automatic Jar Sticker Labeling Machines, Automatic Bottle Labeling Machines, Vial Labeling Machines, Ampoule Sticker Labeling Machines, Self Adhesive Sticker Labeling Machines, all incorporating cutting-edge technology to meet the demands of Packaging and Manufacturing Industries.

As a trusted manufacturer and supplier of Automatic Sticker labeling machines, self adhesive sticker labeling machine or labeler as they are often called, we deal in all type of Bottle sticker labeling machine such as Front and back labeling machine, Double side labeling machine, round bottle labeling machine, Paper Roll Labeling Machine, Wrap-around labeling machine, Vial labeling machine, ampoules labeling machine, Hologram Sticker Labeling Machine etc.

High Demand of Om Bhagwati make Sticker Labeling Solution For All Type Of Products

- Shampoo Bottle Labeling Machine

- Hair Oil Bottle Labeling Machine

- Liquor/Whisky Bottle Labeling Machine

- Liquid Bottle Labeling Machine

- Single Side Battery Labeling Machine

- Battery Sticker Labeling Machine

- Honey Bottle Labeling Machine

- Fruit Cream Labeling Machine

- Cosmetics Bottle Sticker Labeling Machine

- Syrup Bottle Labeling Machine

- Paper Roll Labeling Machine

Provides excellent quality Automatic Sticker labeling machines for bottles of all shapes and sizes. Labeling Solution for Shampoo Bottle. Apart from working towards manufacturing machines, we also work as a dealer and stockiest for these products and supply them to reputed firms in the public as well as private sectors of Pharma, Automotive, FMCG, Packaging, and Appliances. Our sticker labeling machines are designed in a unique manner and are manufactured using premium quality components, and advanced technology in accordance with international quality standards and under the purview of certified expert professionals. Our customers and clients enjoy the unique designs, solid framework, and fine printing process and stand out in the market. Easy handling, long-lasting operating ability, spectacular performance, and user-friendly labeling machine prices make our products highly satisfactory in the manufacturing and packaging market.

Automatic Bottle Sticker Labeling Machine

Automatic bottle labeling machine also known as bottle label applicator, labeler machine for bottles, label applying machine, automatic bottle labeling machine, bottle sticker labeling machine, bottle labeler, bottle Sticker labeling machine have a fully programmed, tough, and straight-forward model. These machines are convenient-to-use and enduring as well & Best sticker labeling machine price. Packaging industries across the globe widely make use of bottle sticker labeling machines. All kinds of bottles could be labeled using this machine. The Labeling machine consumes less energy and is environment-friendly as well. There is an alarm fitted in the machine to prevent any kind of shortcoming. The machine is made up of good quality parts to ensure smooth operation. These bottle labeling machines have essential highlights of standard gear. There are no label data input/recoveries for any label size available. The machine has integrated speed of the label dispensing, conveyor and has a top hold belt system as well. The machine is assumed to be practically maintenance free-machine.