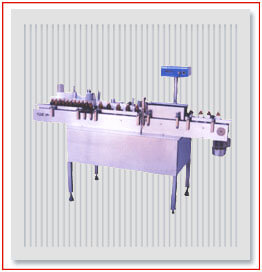

Wrap Jar Sticker (Self-Adhesive) Labeler Machine

Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labelling Machine Mode, Suitable for Labeling on Bottles, Jars, Tins and other round objects. The Machine incorporates latest sophisticated Micro Processor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system.

Salient Features:

- No change parts for container and label size.

- Built In A.C. Freq. Drive System. Output 40 to 100 labels per minute.

- Fully stainless steel finish.

- Optionally online coding system. Suitable for Wrap-around and Overlap Labeling

Technical Specification :

| Label Data Inputs | Not required due to In Built Automatic Label Length Detection System |

| Label Placing Adjustments | User Friendly And Simple |

| Pass-Word System | Fully Protected, Not required by operator |

| Voltage Fluctuations | Self-Protected for Voltage Fluctations |

| Speed Variation | Single Point Speed Variation Control - Synchronizing all operations |

| Label Length | Unlimited Label Length |

| Maintenance | Virtually Maintenance Free Machine |

| Spool | Largest 400mm diameter |

For Round (Diff. Dia.) / Perfect Square Containers.

This is used for full / partial wrap-around labelling on round / square containers of different sizes. The machine operates at the speed of 100 / 200 / 300 containers per minute depending on the lable length. Separate drives for conveyor, wrap-around and space creators are useful for precise labelling on various products with varying label sizes.

specifically designed for ampoule and vial labelling with max speed up to 350ppm. Optional OCR/OCV features enable your global Track & Trace requirement. This machine is ready for integration with Sea Vision and Trace link Track & Trace system.

- Optional feeding turn-table to allow smooth and stable material feeding and collection.

- Fallen bottle diversion mechanism ensure smooth and uninterrupted operation by diverge fallen bottle to rejection box.

- Bottle separation by separate wheel or split conveyors with variable speed allows labeling at high speed

- Optional timing screw for bottle separation if extra separation consistence is necessary.

- Rich choice of coding devices including high speed hot-stamping coder, continuous ink jet printer, thermal ink jet printer, laser printer, and thermal transfer printer.

- Inspection function: Optional inspection and rejection devices for missing label, missing code, or wrong code are available

- User friendly HMI provides comprehensive help menu and diagnosis support.

Designed for the extra high speed and high precision requirement of the beverage, food packaging, beauty care, and chemical industries. Achieves different labeling modes including round bottle with orientation and round bottle with multi-labels, oval bottle front/back, square bottle wrap around, square bottle multi-sided, conical bottle etc. Multiple work stations are driven to spin by a cam or by motor while revolving around a carousel, and various methods are available for aligning bottle orientation to ensure fully and precisely controlled orientation of the bottle for accurate labeling. Options available: non-stop label roll change, synchronized coding, vision inspection.

- Use of turn-on belt and wrapping belt together allows high speed rotation of bottles while transporting at close pitch, thus achieves high throughput capacity.

- Support of turning on bottles ensures high precision end-to-end alignment of the label on full round labeling.

- Servo driven timing screw to feed bottles on the trunnion belt at synchronized pace, ensuring smooth transfer of bottles and labeling process even at extreme fluctuation of incoming frequency of bottles.

- Multiple ball bearing supported trunnion design, ensuring quiet and smooth movement of the belt and thus durability.

- Powered label unwind allows use of label roll of up to 500mm diameter, specially designed to cater for the extra long label lengths in full round labeling.

- Various inspection options for missing labels, missing code, code content, and label position etc., and an synchronized automatic rejection mechanism is also available to ensure output quality.

- Various coding device options including hot-stamping, TTO, CIJ, TIJ and laser for synchronized imprinting on the labels. Seamless integration with most common brands of coding devices so that the system can react to and record the alarm signals and status log of the device.

- User friendly HMI, stores up to 50 sets of recipes (including product dimensions, label length etc.) for immediate use on product change.

- Servo driven labeling engine with an emery coated traction roll ensures persistent frictional coefficient; double traction point design ensures consistent label liner tension thus avoids liner breakage and achieves high stopping precision.

- Use of world class control and motion components to ensure long term reliability and stability of the system.

A sticker (self-adhesive) labeler machine, also known as a self-adhesive label applicator or sticker labeling machine, is a device used for automatic application of self-adhesive labels onto various products, packages, or containers. It is commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics.

The main purpose of a sticker labeler machine is to accurately and efficiently apply self-adhesive labels onto products. Here are the key components and features of a typical sticker labeler machine:

1. Conveyor System: The machine is equipped with a conveyor belt or system that moves the products through the labeling process at a consistent speed. The conveyor ensures a smooth and controlled movement of the products for accurate label application.

2. Label Roll Holder: This component holds the roll of self-adhesive labels that will be applied to the products. The label roll holder is designed to accommodate various label sizes and types and allows for easy unwinding and feeding of the labels.

3. Labeling Head: The labeling head is responsible for dispensing and applying the self-adhesive labels onto the products. It incorporates a mechanism that accurately releases the labels from the roll and places them onto the products. The labeling head may use different techniques such as a wipe-on brush, a blow pad, a vacuum drum, or a tamp pad, depending on the specific requirements of the application.

4. Labeling Controls: The machine includes a control panel or interface that enables the operator to set parameters such as label size, application speed, placement accuracy, and other relevant settings. The controls may also feature programmable options for different label formats or product variations.

5. Sensors and Detection Systems: Sticker labeler machines employ sensors and detection systems to ensure precise label placement. These sensors detect the position, orientation, or presence of the products and labels, allowing the machine to apply the labels accurately and consistently.

6. Integration with other Equipment: Sticker labeler machines can be integrated into existing production lines or used as standalone units. In integrated systems, the labeler may communicate with other equipment, such as filling machines, capping machines, or packaging machines, to ensure synchronized operation and optimize the production process.

The operation of a sticker labeler machine typically involves the following steps:

1. Product Placement: The operator or an automated system places the products onto the conveyor belt or manually feeds them into the machine, ensuring proper spacing and alignment.

2. Label Roll Setup: The roll of self-adhesive labels is mounted onto the label roll holder, and the machine is adjusted to accommodate the specific label size and shape.

3. Machine Setup: The operator sets the required parameters on the control panel, such as label size, application speed, and placement accuracy.

4. Label Application: As the products move along the conveyor, the labeling head dispenses and applies the self-adhesive labels onto the products based on the predefined settings. The sensors and detection systems ensure accurate label placement.

5. Post-Labeling Operations: After the labels are applied, the labeled products continue along the conveyor for further processing, such as packaging, sealing, or inspection.

Sticker labeler machines offer benefits such as increased labeling speed, improved accuracy, and reduced labor costs compared to manual labeling. They are versatile and adaptable to various product shapes, sizes, and label types, making them widely used in the packaging industry.